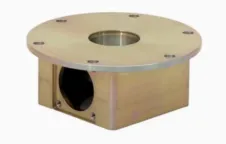

A technology through which the material block fixed on the CNC turning center or lathe rotates with high speed,while the cutting tool moves into the rotating axis to process the workpiece and get CNC turned parts with cylindrical features.

CNC Machining Process-Our CNC Machining Capabilities

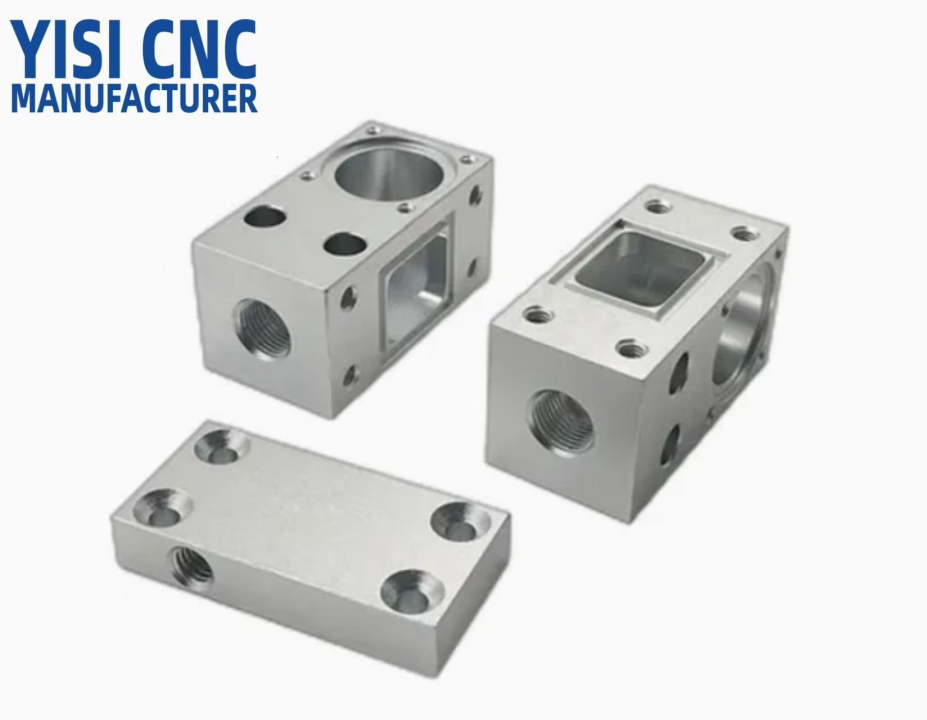

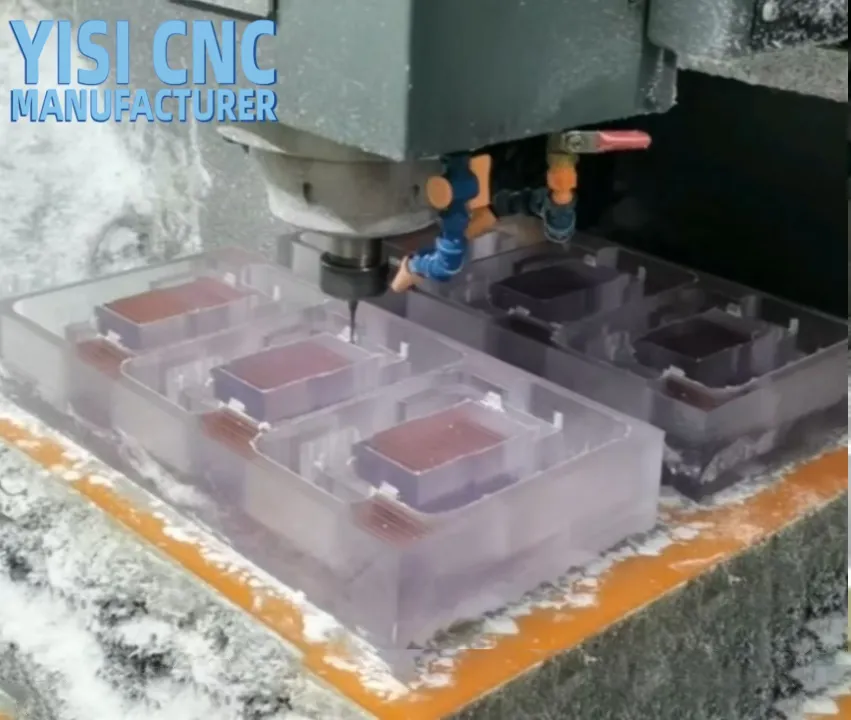

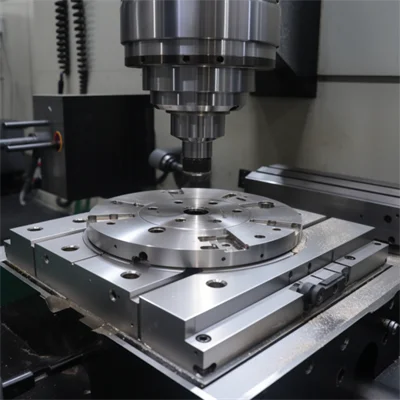

Milling is often regarded as the most common machining process,which refers to utilizing a CNC milling cutter to do circular motion and create milled parts with certain shapes and details in a stationary piece,including slots,holes,notches,grooves,etc.

YiSi CNC sheet metal fabrication services and CNC cutting services are available for both rapid prototypes and low to high-volume production runs of your parts.

CNC Machining Tolerances

Milling: 2000 x 1500 x 200 mm; Turning: 990 mm (length), 431mm (diameter)

10 x 10 x 10mm

Metals & PEEK: +/- 0.01 mm;

Other Plastics: +/- 0.05 mm;

No Drawing:ISO 2768 Medium;

Metals & PEEK: +/- 0.008 mm;

Other Plastics: +/- 0.05 mm;

No Drawing:ISO 2768 Medium;

Metals & PEEK: +/- 0.004 mm;

Other Plastics: +/- 0.05 mm;

No Drawing:ISO 2768 Medium

CNC Machining Materials

Plastic

POM (Delrin), ABS, HDPE, Nylon, PLA, PC, PEEK, PMMA (Acrylic), PP, PTFE, etc.

Metal

Aluminum, Steel, Stainless Steel, Brass, Copper, Titanium, etc.

Composite

Carbon fiber, PC glass, PA glass, etc.

CNC Machining Finishes

| Finishing | Description | Materials | |

|---|---|---|---|

|

Standard/As machined | Machines and deburrs parts, chamfers edges | All available metals |

|

Bead Blast | Reduce machining marks | Aluminum, Titanium, Stainless Steel, Brass |

|

Anodizing Type II | Creates a thin, porous, corrosion-resistant coating | Aluminum |

|

Anodizing Type III (Hard coat anodizing) | Creates a hard, thick, wear-resistant porous oxide | Aluminum |

|

Passivation | Improves corrosion resistance | Steel, Stainless Steel |

|

Powder coat | Creates strong wear and corrosion-resistant coating | Aluminum, Steel, Stainless Steel |

|

Tumbling | Removes sharp edges, burrs, and marks | Aluminum, Steel, Stainless Steel, Brass, Copper |

|

Electropolishing | Improves brightness and reduces corrosion | Steel, Stainless Steel |

|

Nickel Plating | Creates a nickel coating to resist corrosion, oxidation and wear | Aluminum, Steel, Stainless Steel |

|

Zinc Plating | Creates a zinc coating to resist corrosion, oxidation and wear | Steel, Stainless Steel |

|

Black Oxide | Minimizes light reflection and improves corrosion resistance | Steel |

Inspection reports can be delivered with goods as your request CMM, laser scanners, and other instruments to inspect CNC parts Long-term or seriously vetted manufacturing partners ISO 9001:2015 certification and CE certification Ensure the specification of each part is correct Certification and test reports of materials are available

The Process of Your Order

Want to get an online CNC machining quote instantly?

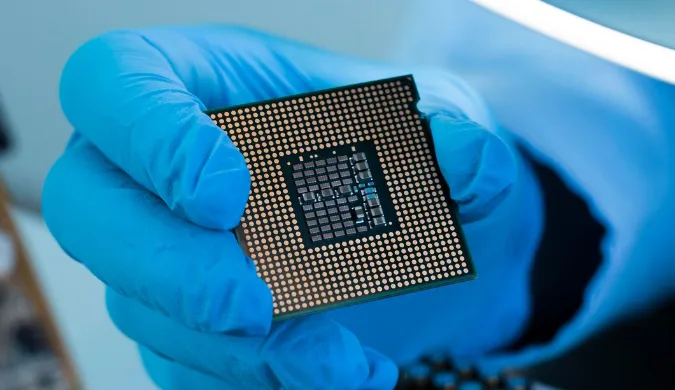

Get Your QuoteCNC (Computer Numerical Control) Machining is a subtractive manufacturing method, which adopts computerized devices to remove the extra materials from the blank and complete required tasks with CNC machine tools, to produce the final designed CNC machining parts. The machine tool, blade material, speed and feed, blade angle, cutting parameters, coolant, workpiece material, and more factors will affect the quality of the CNC machining service.

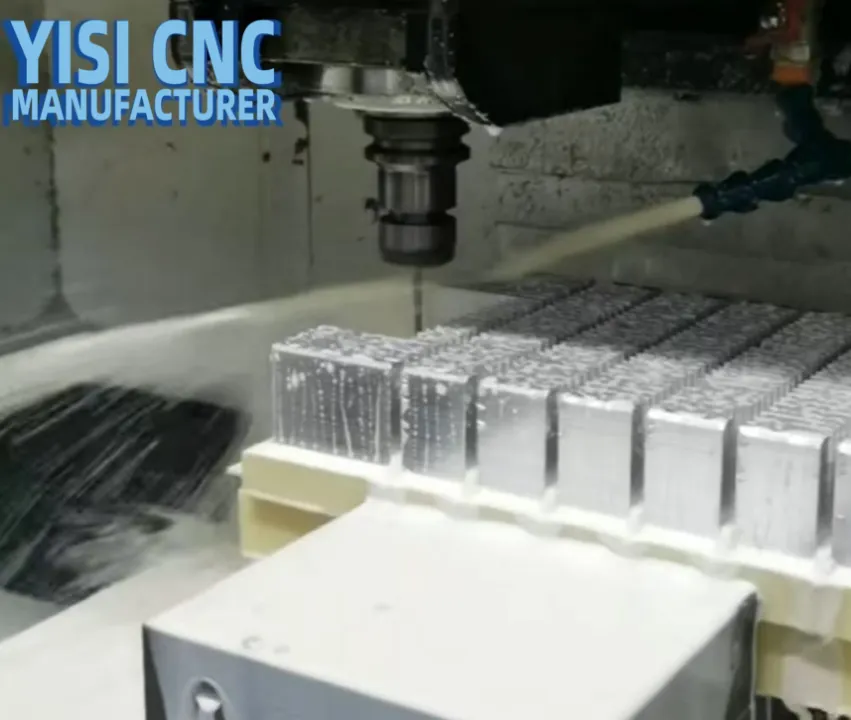

The CNC machining process generates the final part through the subtraction of material. CNC machines are run by digital computers that control the movement of the equipment. The process of CNC machining will go through:

- Load the CAD (Computer Aided Design) file into CAM (Computer Aided Manufacturing) software.

- Determine tool paths based on the part geometry.

- CAM software creates digital instructions or G-Code tells the machine what to do and how to do it.

- CNC machines execute the operations as the programming language.

- Cost. Conventional machining is often less expensive, more cost-effective, and more efficient for smaller jobs. CNC machining is more expensive for little work, but it is more efficient and cost-effective for larger jobs.

- Production. The final conventionally machined product's quality is mostly determined by the machine technician's or operator's skills and talents. Geometry is encoded into the software in CNC machining, reducing the risk of human error in the quality equation.

- Repeatability. Because it is impossible to guarantee a high level of part consistency due to the human factor, traditional machining is best suited for short production runs or a single unit. Because machines are controlled by computer commands, it is simple to create similar parts or components, making CNC machining ideal for the mass production of exceedingly consistent things.

- Requirements. Each machine requires a separate operator, and directing the tools necessitates a large degree of specialist involvement. To make a variety of items, operators of conventional machining must have extensive knowledge, talents, and experience. Because the CNC process requires minimal operator involvement, a single operator may run numerous machines with a high degree of accuracy and precision, lowering labor costs.

CNC machining offers parts, components, and products for almost all industries, typical applications are including automotive, aerospace, electronics, agriculture, food, medical, oil and gas, military, marine, household goods, semiconductor, consumer, etc.

CNC machining is a profitable manufacturing method for precision components, it brings plenty of advantages.

- Minimize the material waste

- Avoid human errors and defects

- Higher accuracy and more efficient production

- Mitigate the possibility of accidents

- Bring down the manufacturing cost

- Decreases the energy losses

± 0.005"or 0.13mm is the standard tolerance for machined metal parts,and+/-0.010" is common for plastic parts. The specific tolerance is depending on the material and drawing. We can discuss tight tolerances based on your drawing.

When you start a project, you should know the cost of the CNC machining service needed. In short, the CNC machining cost is determined by the material, part size, machine type, design complexity, quantity, etc. Below are some typical machining costs in different conditions.

- 3-axis CNC Turning: 20$ per hour

- 3-axis CNC Milling: 20$ to 30$ per hour

- 4-axis or 5-axis CNC Milling: 35$ to 50$

- Aluminum 6061: $25 per block

- Stainless steel 304: $90 per block

- ABS: $17 per block

- Nylon 6: $30 per block

In addition, there are also additional costs that need to be included in the total cost, such as the surface treatment or post-processing cost when the part require special surface finishing service, and shipment cost, especially for a large amount of parts or large-sized products.

How do you know the CNC machining cost? We have a particular system to calculate the cost of machined parts quickly from a CAD file, if you want to know the price of components, you can go to our online quoting page, and upload your CAD drawing to get an instant CNC machining quote. Our quote is completely free and supports multiple formats, just simply drag your 3D file to the correct place and leave your custom requirements, and you can find how much your custom part cost with CNC service.

To reduce or save CNC machining costs, you can start with those factors that affect the cost.

- Choose the right material within your budget. For example, aluminum is one of the cheapest metals to machine and it is the proper material for many industries.

- Optimize your design. The drawing features will affect the machining time and difficulty, choosing the right wall thickness, radii, and other features will save time and cost.

- Reduce complexity. The more complex the part is, the more expensive it will be.

- Consider the size of the workpiece. The less material you use, the lower the cost will be.

- Set-up costs. Reduce the number of part rotations or repositioning needed to minimize the set-up cost.

- Tolerances. Only use tight tolerance when it is essential.

- Reduce surface treatment. Too many surface finishes will inevitably increase the total price.

When it comes to the equipment for CNC machining services, you should understand the machining center. A CNC machining center is primarily an advanced CNC manufacturing machine tool that based on a computer-controlled automation system, can perform a variety of machining operations with high precision, to modify the shape of the workpiece or part to be machined. There are two types of machines. One of them featured in the material to be processed is fixed, attached and stationary to the machine, while the cutting tool moving to work, which is suitable for square or rectangle shapes, another type is reverse, the part is rotating while the tool remains static, allows to mechanize other types of pieces. For example, the common CNC milling machines with an automatic tool changer, a table that clamps the workpiece in place, and an enclosure are classified into the CNC machining center. The spindle orientation is its most fundamental defining characteristic. According to the number of axes, there are 3-axis/4-axis/5-axis machines.

You can choose a variety of different CNC machines according to your budget, material and part to be processed.

- CNC lathe machines

- CNC milling machines

- CNC drilling machines

- CNC routers

- CNC plasma cutting machines

- CNC laser cutting machines

- CNC waterjet cutting machines

- CNC electrical discharge machines

Online CNC Machining Services

Want to shorten production cycle and reduce cost of your machinery components? Integrated multiple advanced technologies, CNC Machining Services can simplify the manufacturing process and speed up large batch production of machined components, as well as achieve a higher level of accuracy and precision.

YiSi CNCYiSi CNC provides rapid online CNC machining according to customer requirements. Send your CAD files or inquiry to us, a fast, free online CNC quote of required CNC components will be back. Get your CNC Machining Parts into processing in the shortest time.

Precision CNC Machining Services – Custom China CNC Machining Parts Manufacturer & Factory

CNCLATHING.COM – As an accomplished CNC machining company and CNC shop, YiSi CNC Metal Manufacturing Co., Ltd has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 16 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components.

With the help of high-level technology and efficient equipment, as well as rigorous attitude, we passed the ISO9001:2015 quality certification, which supports the long-term development of YiSi CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc. YiSi CNC professional CNC parts machining involves CNC metal parts manufacturing, plastic CNC machining, and some difficult materials. Our CNC machining products can be utilized in a broad range of industries.

Advantages of YiSi CNC Machining Services

- Efficient CNC machining factory for mass production rapid prototyping service

- Average 7 days turnaround time and 99.85% on time delivery

- Multiple options of machining materials to meet specific properties.

- Fast free quotation within 24 hours after inquiry

- High customer satisfaction and loyalty

- Rich design and manufacturing experience

If you are looking for quality CNC machining services near me, our low cost CNC custom machining will review the design, build your quote, assess the cost and get your non-metal or metal fabrication parts into production orderly and efficiently.

Applications of YiSi CNC Machining Services

CNC machining parts are all around you, they may be important components of your car and also can perform vital functions in your electrical equipment. YiSi CNC is an accomplished CNC supplier that engaged in a broad range of CNC machining applications.